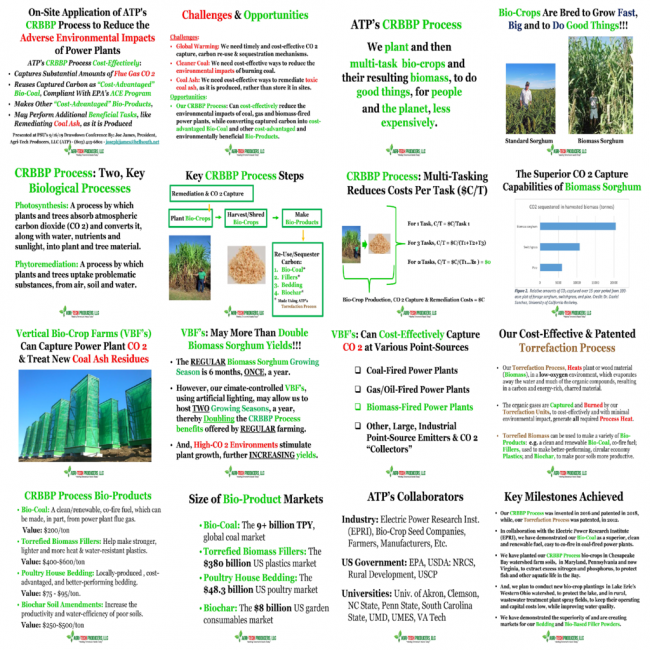

I would like to inform you about the latest application of our recently-patented Combined Remediation Biomass and Bio-Product Production (CRBBP) Process, on-site, at coal-fired power plants, to cost-effectively reduce their adverse environmental impacts.

Using our CRBBP Process, we plant and then multi-task fast-growing bio-crops and their resulting biomass to do good things for people and the planet, less expensively. And, the multi-tasking features of the CRBBP Process spread the cost of growing and using our bio-crops across several tasks, making the cost of each task, including the remediation of soil and water, CO 2 capture and the production of bio-coal, considerably less expensive.

According to an analysis done for us, by the University of California-Berkeley, over a 15-year span, equivalent acreages of our preferred bio-crop (Biomass Sorghum) will extract 3 times the CO 2 of newly-planted pine trees and 2 times the CO 2 extracted by other crops, including bio-crops, like switchgrass.

In addition to extracting relatively large amounts of CO 2, our bio-crops, due to their fast growth and size, are also great at phytoremediation, as they extract relatively large amounts of problematic substances from soil and water, including the arsenic and heavy metals found in coal ash.

Therefore, the on-site application of our CRBBP Process can help a power plant reduce its carbon emissions, handle its coal ash challenges, and benefit from the on-site production and co-firing of a clean and renewable, high-Btu, bio-coal fuel, essentially made from the CO 2 our CRBBP Process captures.

Day

Monday Poster Session

Related Conference Themes

Electricity Generation

Materials & Waste