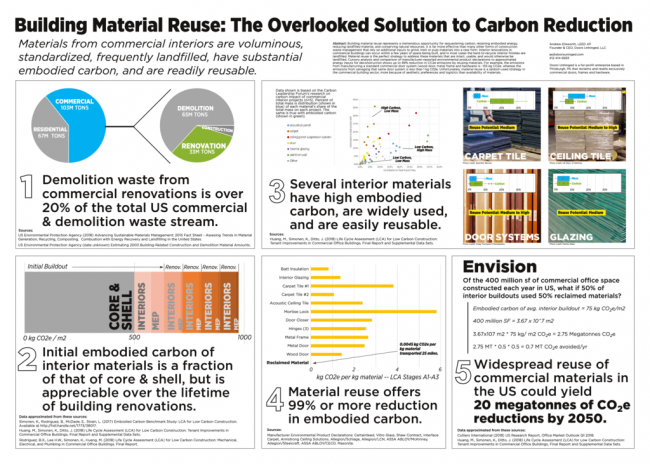

Building material reuse represents a tremendous opportunity for sequestering carbon, retaining embodied energy, reducing landfilled material, and conserving natural resources. It is far more effective than many other forms of construction waste management that rely on additional inputs to grind, melt or pulp materials into a new form.

Interior renovations in commercial buildings can occur within a few years of space being built, and in most cases the hard-to-recycle interior finishes are landfilled. Material reuse is the perfect strategy to address these materials that are intact, usable, and would otherwise be landfilled. Cursory analysis and comparison of manufacturer-reported environmental product declarations to approximated energy inputs for deconstruction shows up to 99% reduction in CO2e emissions by reusing materials. For example, the emissions from manufacturing a standard commercial door system (wood door, metal frame and hardware) is ~155 kg CO2e, whereas the emissions from salvaging that same door system is less than 1 kg C02e.

Unfortunately, material reuse is a seldom-used strategy in the commercial building sector, more because of aesthetic preferences and logistics than availability of materials. This poster presentation will compare emissions of new versus reused across a range of material types, and explore the challenges facing widespread material reuse in the commercial sector.